How to select the grade?

Grade list

From general-purpose resins to super engineering plastics

Compatible with various resins

We support a variety of resins from general-purpose resins to engineering plastics, super engineering plastics such as PPS and LCP. Please select the grade according to the resin you wish to clean.

| Type | Grade | Applicable Resin |

Hot Runner | Filler | Recommended Operating Temperature |

|---|---|---|---|---|---|

| For general-purpose resin | NX-VC2 | PP, PE | ○ (mold opening) |

– | 160~240℃ |

| NX-E | TPE, PVC, PE | ○ (mold opening / molding) |

– | 140~240℃ | |

| NX-A2 | ABS, PMMA | ○ (mold opening) |

– | 180~270℃ | |

| NX-P2S | PP | ○ (mold opening / molding) |

– | 180~260℃ | |

| NX-S | PS | ○ (mold opening) |

– | 200~250℃ | |

| Engineering plastic | NX-VN2 | engineering plastic ABS, ABS, PMMA |

△ (mold opening) |

– | 180~280℃ |

| NX-VK2 | △ (mold opening) |

inorganic (non-GF) |

200~320℃ | ||

| AW2 | △ (mold opening) |

inorganic (non-GF) |

200~320℃ | ||

| NX-VG2 | × | GF | 200~320℃ | ||

| NX-VG3 | Usability improvement grade of High temperature(over 300℃) |

× | GF | 250~340℃ | |

| For high temperature | NX-HG | PPS, PA9T, LCP etc. | × | GF | 180~370℃ |

| For take out screw used | NX-BS | 160~260℃ |

* If you would like the English version of SDS, please contact us using the Contact page for inquiry.

Hong Kong +852-2730-2129 SINGAPORE +65-6327-2038

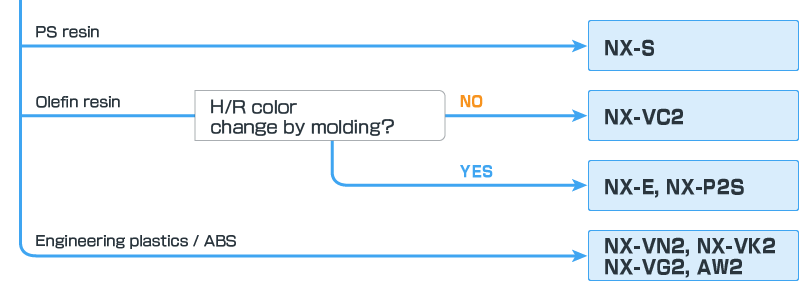

Grade selection guide

To clean effectively

Choose the most suitable grade

Choosing the right grade is important for effective cleaning, and the resin polarity has a significant effect on residue. Please select the grade of Celpurge referring to the following points.

Point 01

Determine by classifying each resin

01Olefin resin,

02Engineering plastics / ABS resin,

03Super engineering plastic

The effective cleaning mechanism is different for each resin.

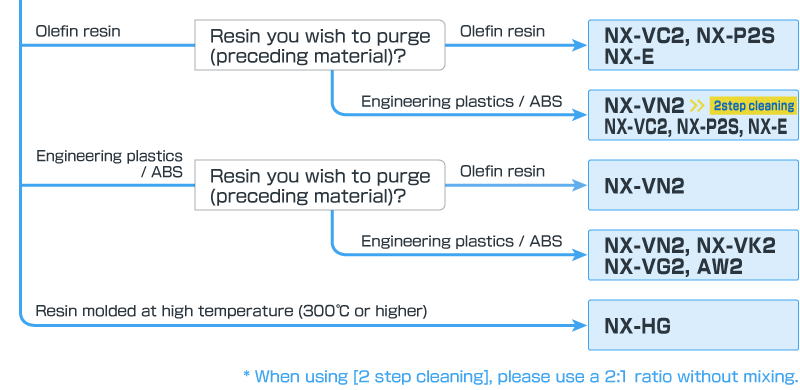

Point 02

Consider not only preceding material but also subsequent material

It is important to prevent residue of purge agent.

- Olefin resin

- Due to its low discharge capacity, engineering plastic grades such as NX-VN2 may not be discharged well. When changing the color and material of olefin-based resins, please select olefin grades such as NX-VC2, NX-E, NX-P2S.

- For resins with high processing temperatures such as super engineering plastics

- Please select NX-HG for high temperature resin cleaning. When used for super engineering plastic applications, it is recommended to dry before use.

- To change materials from engineering plastics to olefin resins

- Discharge engineering plastics with engineering grades (NX-VN2, NX-VK2, NX-VG2, AW2), then discharge the engineering plastic grade with olefin grade (NX-VC2, NX-P2S, NX-E), Two-step cleaning is recommended.

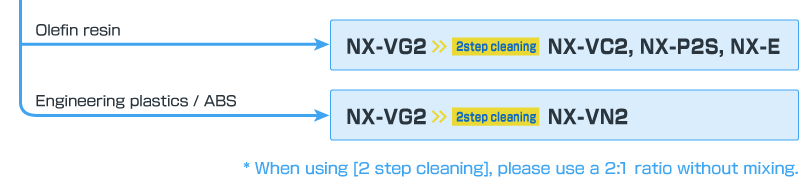

- For cleaning of black spots and carbonized material

- Please select NX-VG2 with GF. It is more effective to use NX-VN2 after NX-VG2. Please use a 2:1 ratio without mixing. (If there is a slight black spot, a grade with no filler added is also effective.)

- Use Celpurge for sealing

- Celpurge can also be used as a sealing material.

After completing the purge with Celpurge, sealing can prevent carbonization by stopping the molding machine with a fixed amount of Celpurge.

* Please use non-filler grade for sealing. - Celpurge as screw removal agent

- Please use the grade NX-BS. It reduces the work load when removing and cleaning the screw.

If you are unsure about grade selection

Please refer to the flow chart below.