How to use :

For extrusion molding

How to use : For extrusion molding

How to use

Changing the rotation speed during cleaning will change

the direction of the resin flow and is more effective.

01After finishing the molding process, discharge all the material in the extruder.

02Load the Celpurge into the hopper and rotate the screw to discharge the Celpurge.

03When no previous material remains, the discharged resin turns white.

04Load the subsequent material to flush out the remaining Celpurge, completing the cleaning process.

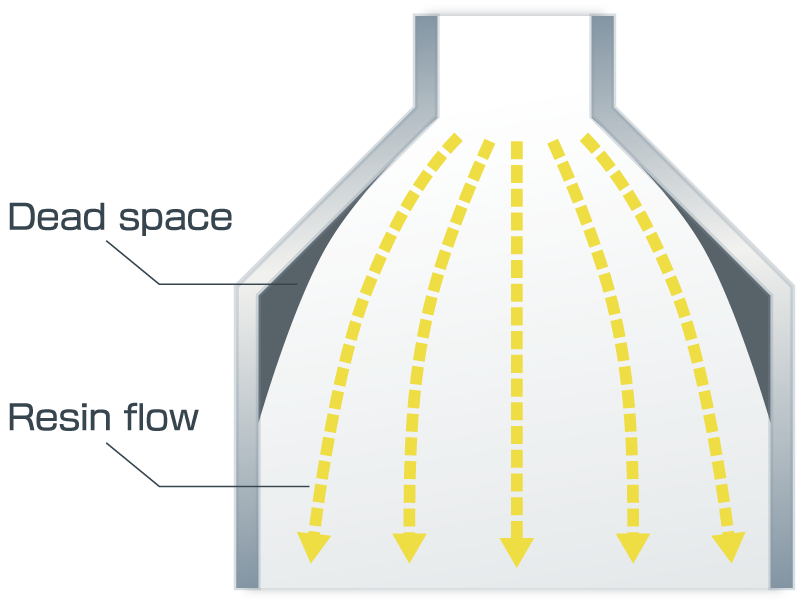

Residue in dead space due to

viscosity and design of die head

Celpurge is also effective in extrusion molding, unfortunately, not all extrusions are perfectly clean.

This is because a dead space is created where the direction of the flow path changes, and because a resin with a higher viscosity than used in injection molding is used.

For example, when extruding a sheet or film using a T-die, there is always a portion that remains around both sides of the T-die.

Molding method

Excellent molding methods are as follows.

The required amount depends on the die shape and capacity.

Inflation / film molding, tube molding, profile extrusion molding, compounding / kneading

Hong Kong +852-2730-2129 SINGAPORE +65-6327-2038

Usage by purpose

Inflation cleaning

Effective for cleaning and color change of inflation molding machine!

Celpurge NX-E is used for cleaning and color change of polyethylene inflation molding machine.

It can be used by mixing with the product resin you are using.

Film formation and winding is possible.

- Appropriate dilution ratio is NX-E / polyethylene = 2/1 to 1/1 ratio.

- Supports LLDPE, LDPE, HDPE.

The end point of color change is easy to monitor. - The color does not gradually fade, but the color disappears in stripes, so it is easy to determine the end point. It can also remove slightly carbonized material.

- Ability to remove black dots.

* If film formation is difficult due to uneven thickness, increase the temperature by 5-10℃.

* If film formation is not required, blending with product resin is not necessary.

/ Compatible grades / NX-E

Cleaning of kneading and

compound (granulation)

Effective for compound extruder that makes pellets!

Celpurge can also be effectively used in extruders for compounding pellets.

It is effective to change the rotation speed during cleaning to change the speed of the resin flow.

Also, if you load the Celpurge before removing the screw, screw removal is easier.

However, cleaning under the hopper is not possible because the cleaning effect is not achieved in the unmelted state.

01After finishing the granulation process, discharge all the materials in the extruder.

02Open the die and remove the screen mesh.

03Load the Celpurge into the hopper, and rotate the screw while the vent is open to start the flow of Celpurge.

04When resin turns white which indicates no residue of the previous material, stop the screw rotation, open the die, and remove the resin remaining in the diehead.

05Start flow of the next material with the diehead open, and replace it until cleaning completed.

Clean the bottom of the hopper with melted strands (with audio)