How to use :

For injection molding

How to use : For injection molding

How to use

Standard consumption and procedures

01When cleaning the cylinder/screw of the injection molding machine, after molding the preceding resin, set the molding conditions as shown in the table below and repeat the measuring and injection.

02After purging, change to molding conditions for the subsequent material and after stabilizing temperature, use the subsequent material to discharge the Celpurge.

Molding Condition

| Metering | Cylinder temperature | Screw rotation speed | Back pressure | Injection speed |

|---|---|---|---|---|

| 10-30mm | same as previous material | 50-70% | 2-10% | 70-99% |

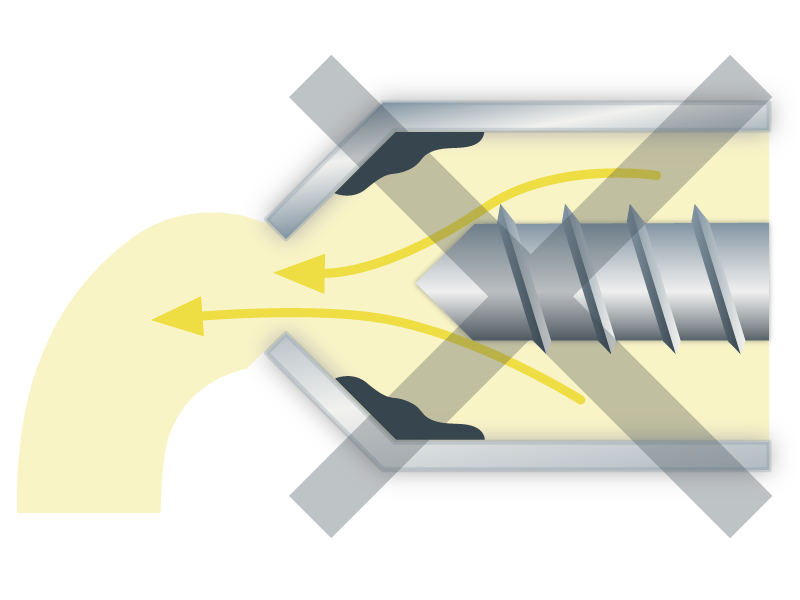

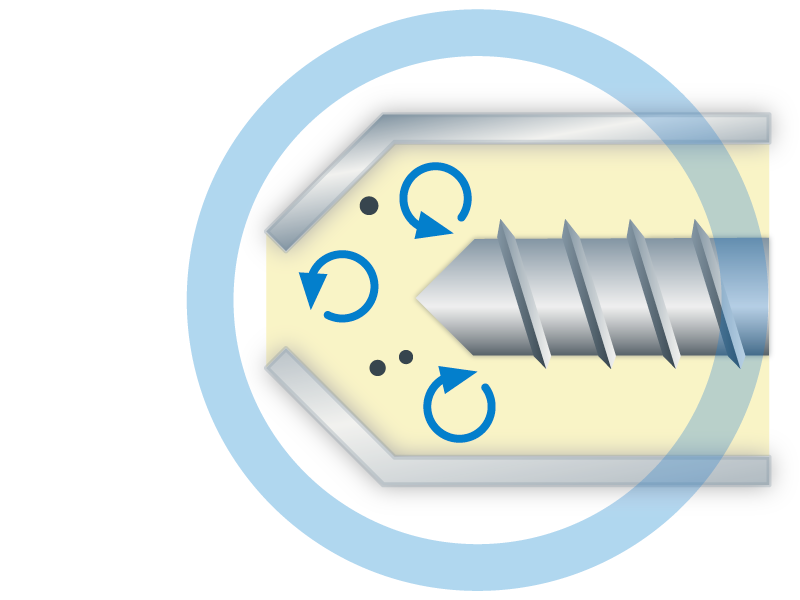

Back pressure set as 2% to 10%

- Do not use high back pressure!

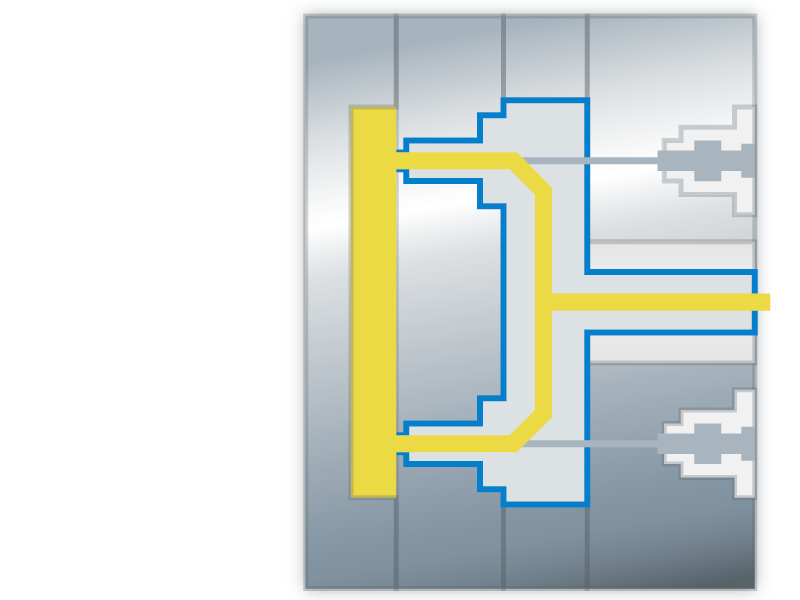

For Celpurge cleaning, we recommend that you reduce the metered unit and continue purging.

This is because contaminant remains in the dead space, especially the nozzle area where removal is difficult.

This “back pressure purging”, in which the back pressure is increased to allow the resin to flow automatically, is sufficiently effective, but it is not effective if the Celpurge leaks due to weak pressure halfway through.

- With proper back pressure

- When purging by metering / injection operation, apply a back pressure of about 2-10% so that the Celpurge does not leak too much from the nozzle.

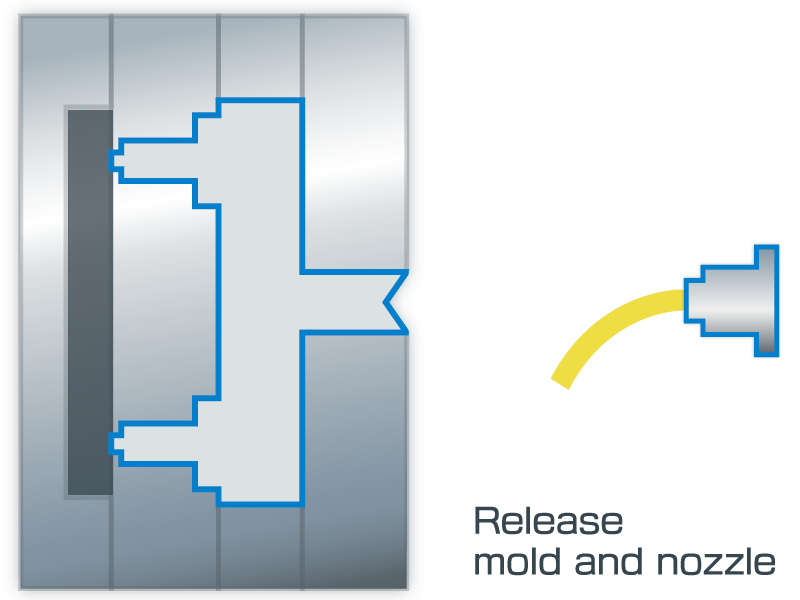

If transparent resin remains

discontinue molding and use an airshot instead

With transparent resins such as PC, PMMA, and transparent ABS with color, the residue is easily visible. Minor residues that are not a problem can be seen as white streaks.

Residues cannnot be removed easily during molding.

If residue in transparent resin is a problem, stop the molding process, set the metering to a minimum, separate the nozzle from the mold, and continue purging by air shot method.

Similarly, in the case of hot runners, open the mold, repeat injection with low metering, and discharge with air shots.

Celpurge that purges steadily

[Hot runner molds can also be purged(cleaned) with air shots] (With audio)

Celpurge that can be peeled off

[Reduces cleaning and maintenance labor] (with audio)

Hong Kong +852-2730-2129 SINGAPORE +65-6327-2038

Usage by purpose

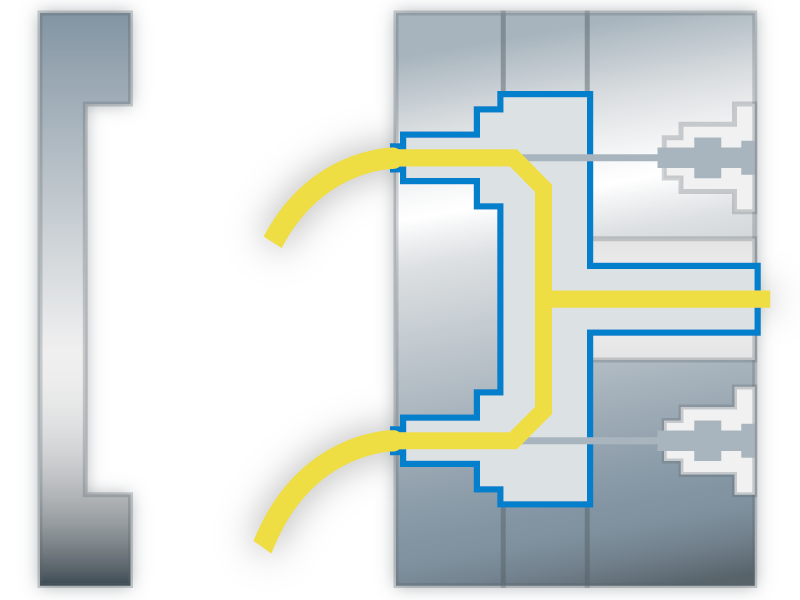

Hot runner cleaning

Use hot runner compatible grade

Cleaning inside the hot runner is possible

Ensure use of suitable grade for specific resin cleaning.

There are two methods, but the amount of Celpurge used is almost the same.

Celpurge for cleaning hot runners (with audio)

01Air shot the Celpurge with the mold open

After molding the preceding resin, set the molding conditions as shown in the table below and repeat the measurement and injection. For valve gate-type hot runners, open and close the gate during injection.

It is more effective to shorten the metering position and to open and close the gate.

| Metering | Cylinder temperature | Screw rotation speed | Back pressure |

|---|---|---|---|

| 10-15mm | Same as preceding material | 50-70% | 2-10% |

* The injection pressure and injection speed have almost no effect on cleaning.

02Mold Celpurge

After the molding the preceding resin, load the Celpurge and mold the Celpurge until the previous material is completely removed. Pay attention to the molding conditions to prevent overfilling of Celpurge.

Also, NX-A2 is more brittle than general molding materials, so take care with molding dies with many bosses and ribs.

/ Compatible grades / NX-VC2, NX-E, NX-A2, NX-P2S, NX-S (, NX-VN2, NX-VK2, AW2)