What is Celpurge?

What are the characteristics of Celpurge?

Based on knowledge and experience as a resin manufacturer

Theoretical design of purging agent

Celpurge is designed by Novacel, which designs, manufactures, and sells various resins centered on polymer alloys. It is a purging agent created on the basis of a series of experiments into purging.

- Compatible with a wide range of resins

- Covers a wide range from general-purpose resins to engineering plastics and some super engineering plastics.

In addition to cylinder / screw molding in injection molding machines, there are several grades suitable for hot runners, inflation film molding, blow molding, and extrusion/kneading machines. - Can be used ‘as is’ in pellet form

- May be used as is without any prior blending.

- Easy-to-understand end point of purging

- Instead of changing little by little, the previous material and color are replaced cleanly, so It is easy to determine the end point of purging.

- Effective for hot runner cleaning.

- Celpurge has overturned the conventional concept that “A purge agent cannot be used for hot runner“.

It is also possible to change the color while continuing molding, We are contributing to the efficiency of the color change process for many customers.

Major grades

NX-VN2

Non-filler for engineering plastics

NX-VG2

GF for engineering plastics

NX-VC2

Non-filler for polyolefin

Hong Kong +852-2730-2129 SINGAPORE +65-6327-2038

What benefits are there?

Quick color and material changeover

The time for setup change can be shortened, and the amount of resin waste and material loss can be reduced, which is eco-friendly and economical. The incidence of foreign material defects can be reduced, and black spots and carbonized foreign material are effectively removed.

For those experiencing difficulties due to the time to change colors and materials, or if you are having trouble eliminating black spots or foreign material on molded products, use Celpurge!

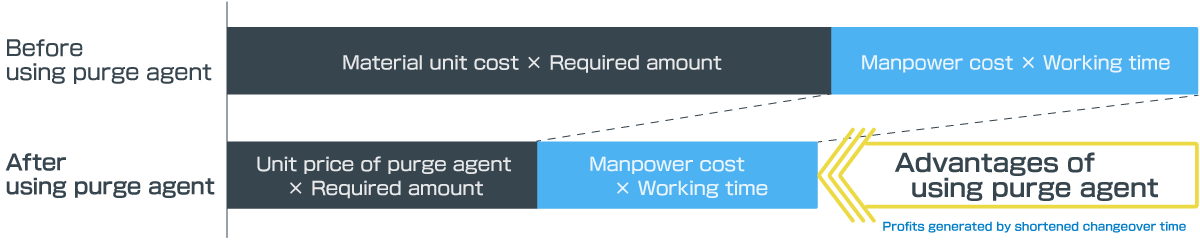

High cost?

-Advantages based on price-

Not just cost reduction!

Increased production efficiency

The price per kg of purging agents is not cheaper than ordinary plastics.

Therefore, if you compare only the price per kg, you will not immediately notice the economic advantages.

However, the actual cost is multiplied by the usage amount, so if the switching time is shortened, the advantages will be significant. Not only will labor costs be reduced, but also production downtime.

With significant cleaning performance, a purging agent is worth using even at higher cost.

Improving productivity is not just about cost reduction.

Improve productivity and increase profits with a purging agent!

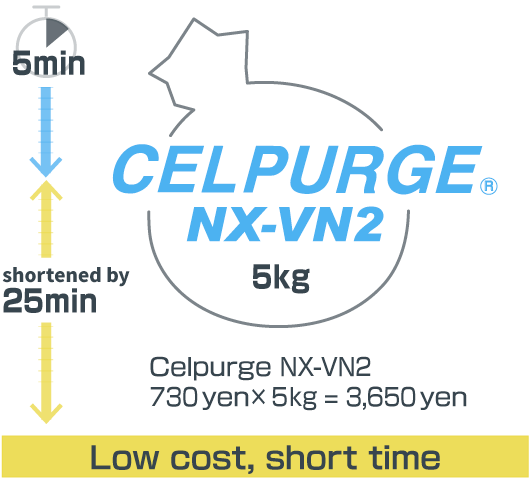

Eg.

When changing the color of ABS on 850 tons injection machine with hot runner, if you use Celpurge NX-VN2, it will be completed in 5 minutes with 5 kg. If you try to replace this with regular ABS, you will need 20 to 30 kg over 20 to 30 minutes.

(Depending on the structure of the mold and screw.)

If the labor cost of 1,500 yen / hr is required, the labor cost for 25 minutes is about 600 yen. Material consumption and labor cost reduction is about 4,950 yen.

However, in 25 minutes it is possible to produce profitable end products.

Eco-friendly

Reduction of industrial waste and CO2 emissions

By using Celpurge, the amount of waste generated during purging can be greatly reduced.

Therefore, it leads to suppressing the amount of CO2 generated when incinerating purge waste,

it is also favorable in terms of environmental protection.

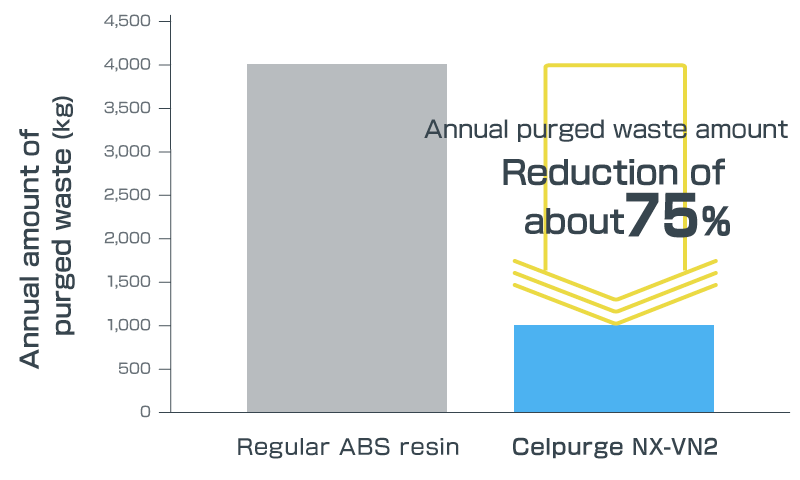

Eg.

When replacing the ABS resin remaining in the hot runner, compare the amount of waste between purging with Celpurge NX-VN2 and purging with ABS material.

Assuming that the consumption of NX-VN2 per year is 1,000 kg, 4,000 kg ABS material will be used.

As a result, the amount of waste can be reduced by 75%,

CO2 generated from waste incineration can be reduced.

What we’re working on

In order to achieve the goals set forth in the SDGs, we will contribute to “nation building” and “human resource development” based on the principle of “human security”, which focuses on the protection and empowerment of each and every person, in order to realize an affluent and dynamic society where no one is left behind.

7

7

AFFORDABLE AND CLEAN ENERGY

CO2reduction

12

12

RESPONSIBLE CONSUMPTION

AND PRODUCTION

Waste reduction