How does it work ?

Activity against carbonized material

- Effects from : Celpurge Characteristics

- – Interfacial tension allows smooth discharge of preceding material

- – Excellent in self-discharge

- – Hot runner cleaning

- Effects from : Activity against carbonized material

- – Scrubbing effect of carbonized material by filler content

- – Maintenance that does not emit carbonized material

Effects from : Activity against carbonized material

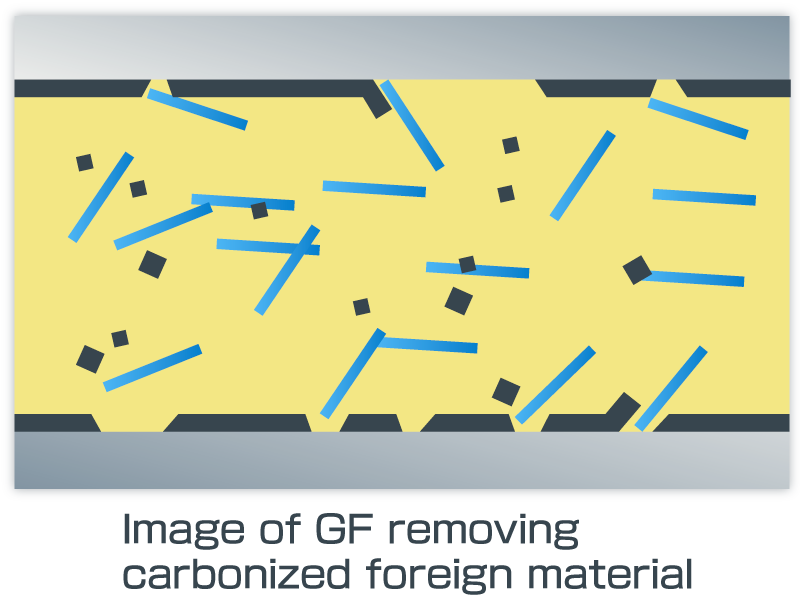

Scrubbing effect of filler

With GF (glass fiber) grade

Removal of carbonized material

When resin is melting, carbonization will occur if exposed to air or heat for a prolonged period.

Why resin is carbonized

- When the interior of the molding machine is empty after molding, the resin remaining on the surface of the cylinder and screw comes into contact with air, resulting in oxidization and carbonization.

- Continuous molding non-stop for several days results in pyrolysis and cross-linking of the resin

- Resin that is originally easily carbonized, such as a flame-retardant resin, is molded at an appropriate processing temperature or higher.

Resin that has been completely carbonized does not become soft even when heated.

Although it adheres strongly to the surface of the metal, it may be released in some way, and if mixed into the molded product, it will act as a “carbonized material” and cause defective molding.

Since GF flows while scrubbing off the surface of the carbonized resin, it effectively removes carbonized material.

It is more effective to use the non-filler grade (NX-VN2) after grades containing GF.

Hong Kong +852-2730-2129 SINGAPORE +65-6327-2038

Maintenance that

prevents formation of

carbonized material

It is better to prevent carbonized material from being formed in the first place, rather then removing it after it has formed.

3 rules that prevent formation of carbonized material

- 01Use Celpurge as sealing material

- To prevent carbonization due to air oxidation, do not empty the molding machine.

Fill the inside of the cylinder with Celpurge to finish the operation at weekends.

At the end of the week, you can start the molding machine from a clean state.

* Please use non-filler grade for sealing. - 02Use Celpurge regularly to discharge carbonized resin.

- To prevent carbonization that occurs during continuous operation, use Celpurge regularly even during continuous operation to discharge carbonized resin.

For example, once a week, set a day and perform cleaning work using Celpurge. - 03Perform cleaning work using Celpurge at least once daily

- To prevent carbonization by resin that easily carbonizes, such as flame-retardant resin,

perform Celpurge cleaning a little more frequently than the above.

For example, perform the cleaning work using Celpurge at least once daily.