How does it work ?

Celpurge Characteristics

- Effects from : Celpurge Characteristics

- – Interfacial tension allows smooth discharge of preceding material

- – Excellent in self-discharge

- – Hot runner cleaning

- Effects from : Activity against carbonized material

- – Scrubbing effect of carbonized material by filler content

- – Maintenance that does not emit carbonized material

Effects from : Celpurge Characteristics

Easy discharge of

preceeding material

due to interfacial tension

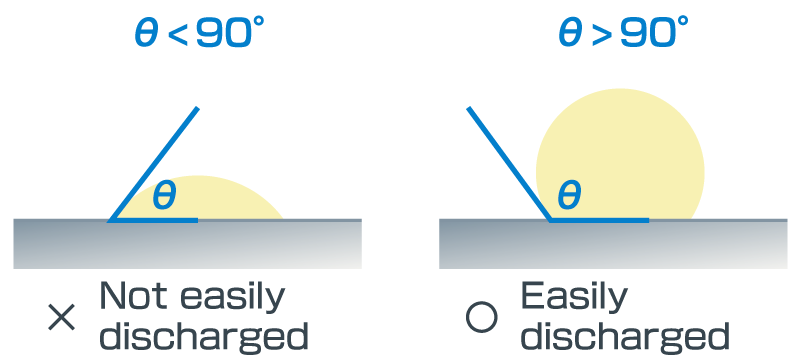

Celpurge controls wettability

It is most effective to use resin with higher viscosity than the preceding material for most efficient purging, facilitating flushing of resin through the flow path.

For the cylinder and screw inner wall of the molding machine, it is more effective to use interfacial tension than viscosity alone.

For example, if water or oil is placed on a frying pan that has been treated with a fluororesin, it will form into a ball shape and prevent the food from burning. This is the logic that was applied.

Celpurge contains a surfactant. By controlling the interfacial tension between the preceding or subsequent material and the cylinder / screw metal surface, the contact angle θ can be increased, allowing the preceeding material to be discharged smoothly.

Hong Kong +852-2730-2129 SINGAPORE +65-6327-2038

Excellent self-discharge

capability

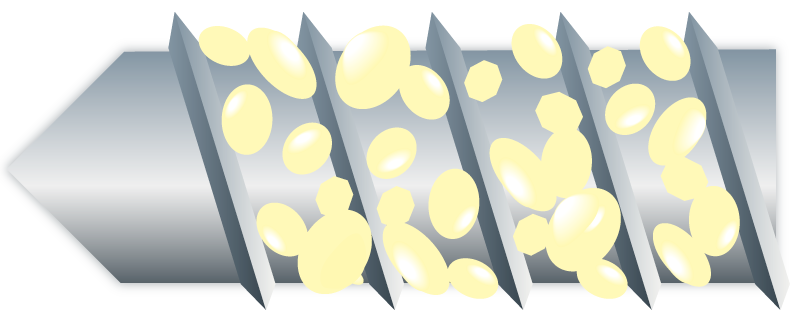

Full coverage over the screw

The purge agent must coat the entire screw and cylinder in order to flush out the original resin from the cylinder.

Celpurge is designed to slide around the surface of the screw by the unique rheology control technology, so it spreads over the entire screw.

Cylinder / Screw

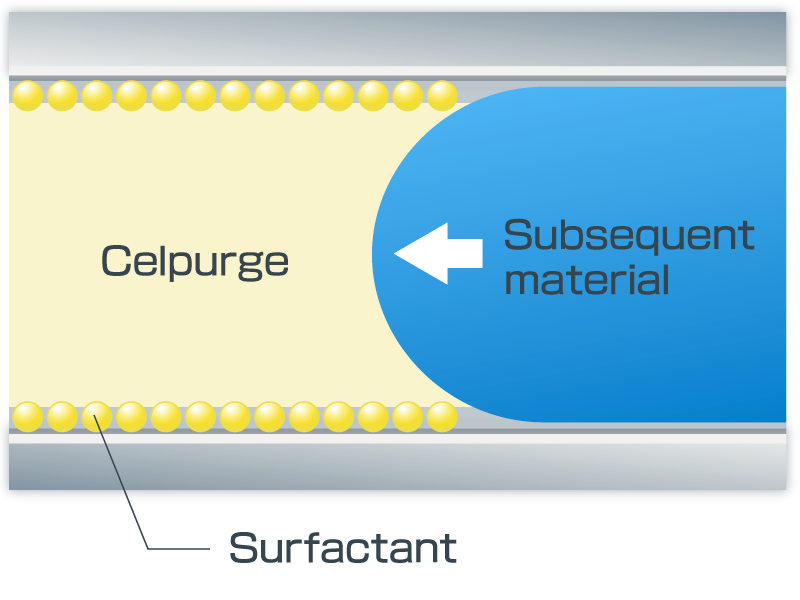

Compatibility is important to prevent resin residue from remaining.

Even with normal resin, the resin near the metal wall will not be easily discharged. The surfactant contained in Celpurge increases the contact angle θ when discharging the preceding material. When loading with the subsequent material, it acts to discharge Celpurge itself.

Celpurge will spread fully over the cylinder/screw surface because the surfactant is positioned between Celpurge and the metal surface of the cylinder/screw (interface).

Hot runner cleaning

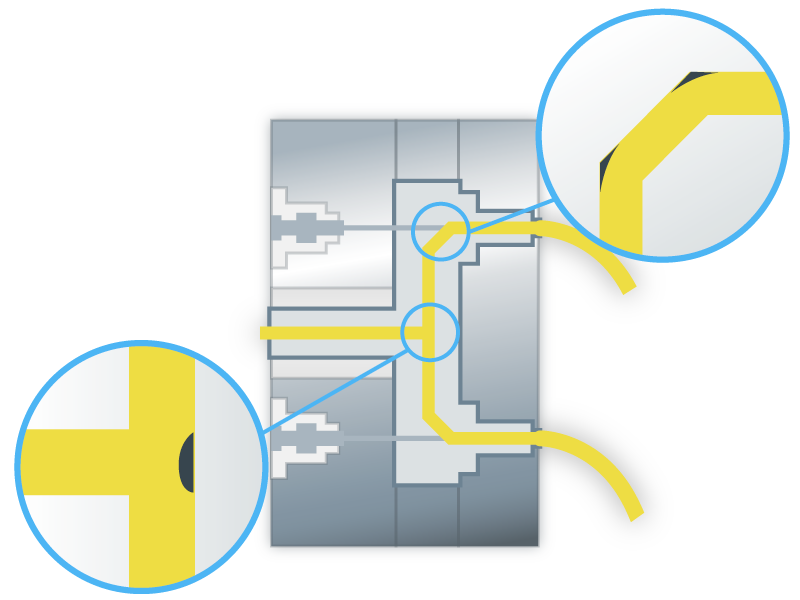

The resin remaining in the dead space is also removed

No residue remains

Due to the structure of the hot runner, there is a dead space where resin tends to remain.

Celpurge is not a viscous-type purging agent, but an interfacial tension controlling purging agent.

Please select the hot runner compatible grade.

Celpurge for hot runner (with audio)

For further details

- Reference materials

“Plastics for molding machine cleaning that expand the applicable range”(JP)

Effect of resin viscosity and polarity on normal resin color changeover process

- Seikei-Kakou

/ The Japan Society of Polymer Processing Technical report “Color change of hot runner mold by resin with surfactant”

A quick overview of hot runner cleaning concepts.- The experimental results of purging between PP and AS resin were shown and interpreted based on the concept of wettability.

Technical Report “A Study on Behavior of Material Replacement during Molding”

We interpreted the normal color change of resin with the idea of wettability.